The success of foundry is more and more based on the digitalization of its processes. The optimal usage of material and resources in the area of your melting department and in the overall melting process is especially crucial due to high energy and raw material costs. The right digitalization supports you in improving your energy and material consumption reduction. Melting Guide, your melting guide by RGU Expert, improves your productivity and makes all previously opaque transactions transparent.

Melting Guide was developed with a full integration of your work environment and processes in mind.

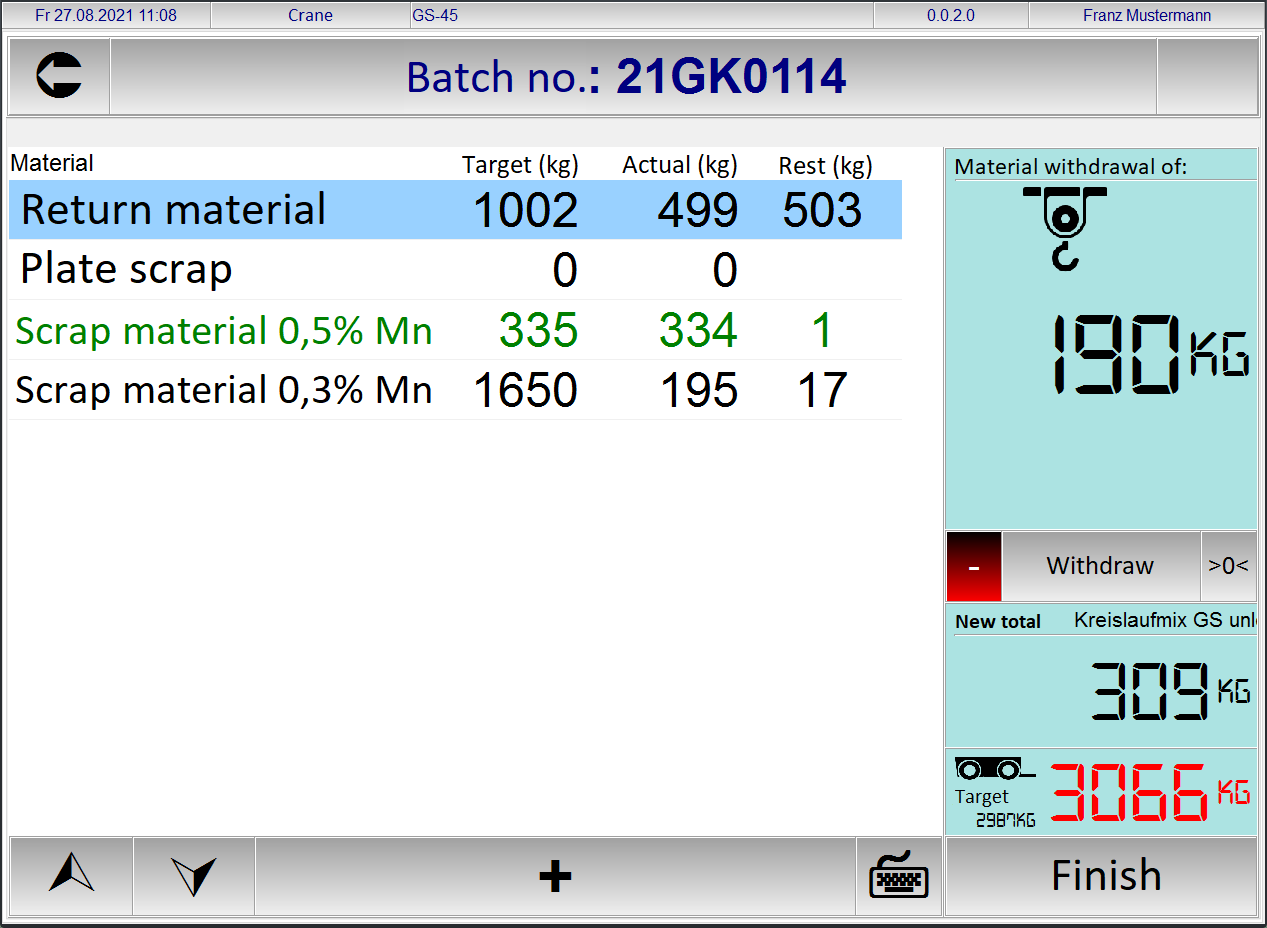

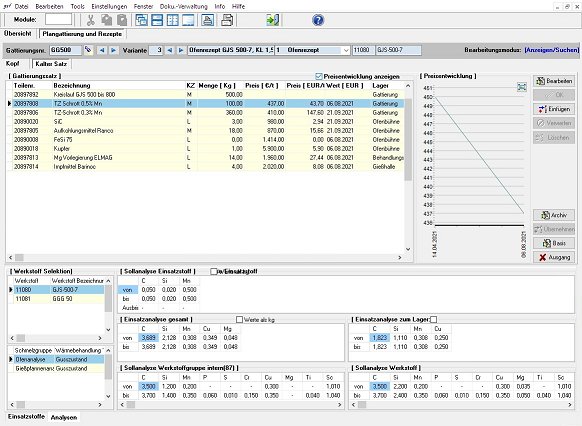

Freely configurable charge composition along the process, inclusion of multiple furnaces, usage of data from scales, spectrometer or temperature measuring devices is integrated into Melting Guide, if applicable. Melting Guide is made with emergency plans, if the automatic capturing of production data is interrupted due to unforeseen circumstances. All operations can also be configured to be operated completely manually.

In the standard version of the system, Melting Guide is fully integrated in the ERP system structura by IPS Expert. Still, all features of Melting Guide can be used alone or in connection with your pre-existing management system. Quality and consumption data can be exported as data records.

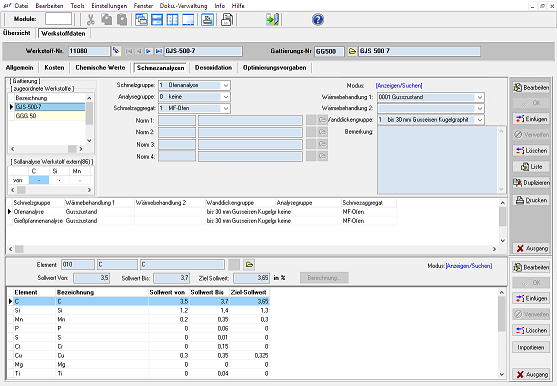

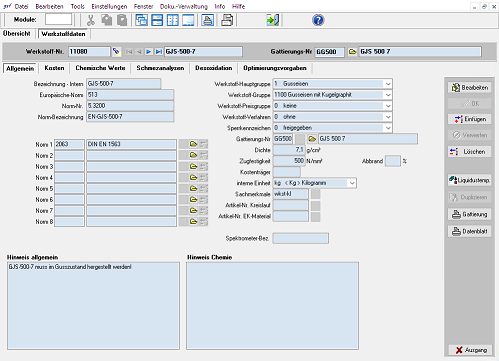

Target charge make-up plans and different variants are easily entered. The reuslting composition is calculated automatically. All target charge make-up plans are built up using specially entered or transfered articles from a pre-existing system. Even stock taking of your raw material and additives is easily done in the system.

GSF expert - Melting guide

by RGU Expert GmbH!

Here you can download all information for creating and optimizing your melting process:

Or contact us directly: info@rguexpert.de

We are looking forward to meeting you!